Understanding Bench Slave: The Essential Tool for Auto Diagnostics

In the fast-paced world of automotive repair, having the right tools can make all the difference. Professionals in the field understand the importance of investing in high-quality equipment to ensure efficiency and accuracy during the diagnostic process. One such indispensable tool in the Auto Diagnostic Tools Store is the bench slave. This article delves into the significance, functionality, and benefits of the bench slave, positioning it as a pivotal asset for automotive diagnostics.

What is a Bench Slave?

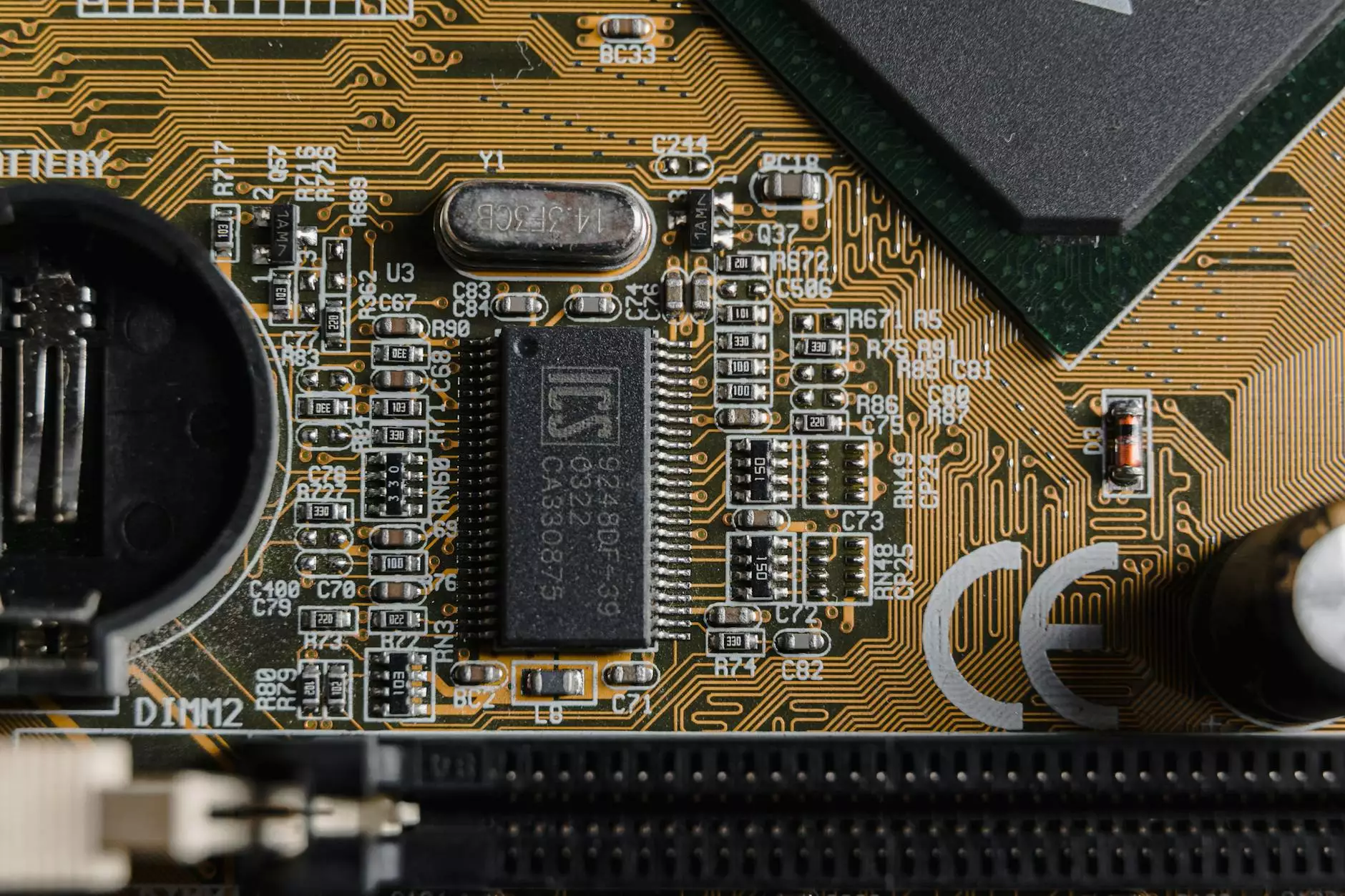

A bench slave is a diagnostic tool used primarily to facilitate the testing and reprogramming of automotive control modules outside of the vehicle. This enables technicians to troubleshoot electronic components effectively without needing to install them back into the vehicle, thus simplifying the diagnostic process.

The Importance of Bench Slave in Automotive Diagnostics

As vehicles become increasingly complex, with advanced electronic systems governing everything from engine performance to infotainment, the need for precise diagnostic tools is greater than ever. A bench slave provides a distinct advantage in diagnostic efficiency. Here are some of the primary reasons why the bench slave is vital in the automotive repair industry:

- Efficiency: Technicians can run tests and make adjustments on a workbench instead of under the hood.

- Time-Saving: Eliminates the need for reinstalling components repeatedly during troubleshooting.

- Enhanced Accuracy: Facilitates a controlled environment for testing, minimizing variables that could affect diagnostics.

- Cost-Effective: Reduces the time spent on diagnostics, ultimately saving money for both the mechanic and the customer.

How Does a Bench Slave Work?

To understand how this tool functions, it's essential to break down its operation. A typical bench slave setup involves the following process:

- Connection: The control module is connected to the bench slave through specific adapters designed to interface with various automotive manufacturers.

- Power Supply: The bench slave provides the necessary power and grounds for the module, mimicking the environment it would operate within the vehicle.

- Diagnostic Software: Technicians use diagnostic software compatible with the vehicle's make and model to run tests, read fault codes, and evaluate performance.

- Data Analysis: Once the tests are completed, the technician interprets the data to identify any potential issues or required reprogramming.

Key Features to Look For in a Quality Bench Slave

Not all bench slaves are created equal. When selecting a bench slave, consider the following features:

- Compatibility: Ensure the bench slave is compatible with a wide range of vehicle makes and models.

- Ease of Use: Look for intuitive interfaces and clear instructions to facilitate quick learning and application.

- Build Quality: Opt for durable materials that can withstand regular use in a workshop environment.

- Technical Support: Choose manufacturers that offer comprehensive support and updates for the diagnostic software.

Advantages of Using a Bench Slave in Auto Diagnostics

Integrating a bench slave into your diagnostic processes can yield numerous benefits:

1. Improved Workflow

With the ability to diagnose outside the vehicle, mechanics can streamline repairs and improve workflow efficiency. This adaptation results in reduced labor costs and faster turnaround times for clients.

2. Increased Learning Opportunities

Technicians can learn from the diagnostic process more effectively. The bench slave allows for experimentation and testing in a safe environment without the complications of installation. This experience builds skills and increases knowledge in automotive electronic systems.

3. Versatility and Flexibility

The capability of a bench slave to accommodate various modules across different vehicles provides versatility that is crucial in a diverse repair environment. Moreover, it allows shops to adapt more easily to evolving technologies in the automotive sector.

Common Applications of Bench Slave in Automotive Diagnostics

The versatility of a bench slave applies to numerous automotive services:

- Control Module Testing: Evaluate the functionality of control modules before installation.

- Reprogramming: Perform software updates and reprogramming as required, ensuring all systems are up to date.

- Fault Code Reading: Quickly identify and review fault codes to assist in pinpointing issues.

- Component Replacement: Help in troubleshooting and validating component replacements before they go into the vehicle.

How to Maintain Your Bench Slave for Long-Lasting Performance

To maximize the lifespan and efficiency of your bench slave, follow these maintenance tips:

- Regular Cleaning: Keep the equipment clean from dust and debris that may affect connections and port integrity.

- Check Connections: Regularly inspect cables and connectors for wear and tear to ensure optimum performance.

- Software Updates: Keep the diagnostic software up to date for compatibility with the latest vehicle models and manufacturers.

- Storage Considerations: When not in use, store the bench slave in a protective case to prevent physical damage.

Conclusion: Elevating Your Diagnostic Skills with the Bench Slave

The bench slave is more than just a tool; it’s an essential part of modern auto diagnostics that can significantly enhance a technician's capabilities. As automotive technology evolves, so too must the tools and skills of those who service these vehicles. By investing in a high-quality bench slave, you are not only improving your diagnostic efficiency but also ensuring your shop remains competitive in the ever-changing landscape of automotive repair.

For those looking to expand their diagnostic tool collection, visiting a reputable Auto Diagnostic Tools Store, such as npshops.com, can offer a wide selection of essential equipment, including the vital bench slave. Equip yourself with the right tools, and watch your automotive repair business thrive.