The Ultimate Guide to Using a Wire Label Maker in Your Business

In today's fast-paced business environment, efficiency and organization are more critical than ever. One often overlooked but incredibly useful tool for enhancing operational efficiency is the wire label maker. This versatile device not only simplifies the labeling process but also contributes to a more organized workspace, which is vital for any successful enterprise.

What is a Wire Label Maker?

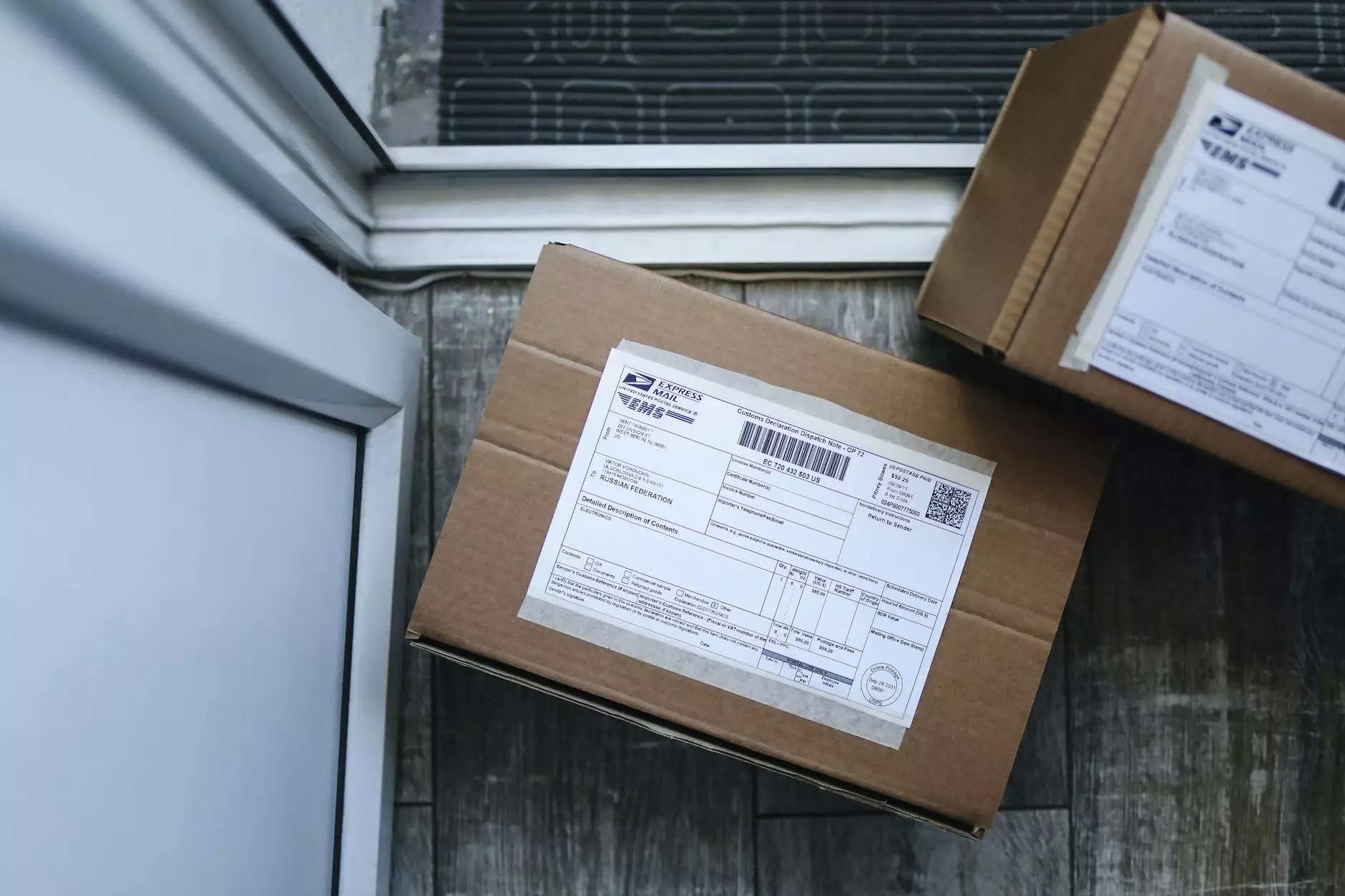

A wire label maker is a specialized printing device designed to produce labels specifically for wires, cables, and other similar applications. These machines allow businesses to create custom labels that can be easily attached to various items, ensuring that everything is correctly identified and easy to manage.

Key Features of a Wire Label Maker

- Customization Options: Create labels with different fonts, colors, and sizes tailored to your branding and identification needs.

- Durability: Labels produced are often resistant to chemicals, water, and abrasion, ensuring longevity.

- Ease of Use: Modern wire label makers are designed for user-friendliness, making it easy for anyone in your organization to operate effectively.

- Portability: Many models are lightweight and portable, allowing for on-site labeling as needed.

Benefits of Using a Wire Label Maker in Your Business

Integrating a wire label maker into your business operations can offer numerous advantages.

1. Enhanced Organization

One of the most immediate benefits of using a wire label maker is the enhanced organization it brings to your workspace. By labeling wires and cables clearly, employees can quickly identify what they need without wasting valuable time searching. This organizational efficiency can lead to:

- Increased Productivity: Employees can focus more on their tasks rather than searching for equipment.

- Reduced Errors: Clear labeling minimizes the chances of misuse or confusion over similar items.

2. Streamlined Processes

Using a wire label maker allows your business to streamline critical processes. This is especially beneficial for:

- Inventory Management: Easily label stock items and equipment, making inventory control simpler and more accurate.

- Installation and Maintenance: Technicians and maintenance teams can quickly identify and troubleshoot issues with labeled cables and wires.

3. Cost-Effectiveness

Investing in a wire label maker can be a financially savvy decision. Here’s why:

- Reduced Labor Costs: With easier identification of wires, less time is spent on labor-intensive search tasks.

- Preventing Damage: Proper labeling can also lead to the prevention of damage from wrong usage, saving costs associated with repairs and replacements.

4. Improved Safety Standards

Safety is paramount in any workplace. In many industries, clear labeling of wires and cables is integral to ensuring safety compliance. A wire label maker can help:

- Prevent Accidents: Clearly marked wires can prevent dangerous accidents resulting from confusion or mishandlings.

- Meet Regulatory Standards: Many industries require proper labeling for compliance, and a wire label maker makes this straightforward.

Choosing the Right Wire Label Maker for Your Business

While there are many wire label makers available, selecting the right one for your unique business needs can be daunting. Here’s what to consider:

1. Volume of Use

How often will the label maker be used? For high-volume tasks, invest in a more robust, high-capacity model that can handle frequent use.

2. Labeling Needs

Consider the specific requirements of your labeling tasks:

- Size and Format: Ensure the device can accommodate the necessary label size and format.

- Compatibility: Check if it works with the types of materials you use for labeling.

3. Ease of Use

A user-friendly interface is essential. Look for models with clear instructions and intuitive controls to minimize training time for your employees.

4. Budget

Pricing can vary dramatically based on features and capabilities. Set a budget that balances quality and cost-effectiveness to find the best wire label maker for your business.

How to Implement a Wire Label Maker in Your Operations

After selecting the right wire label maker, the next step is to implement it effectively into your organizational processes. Here are some steps to consider:

1. Train Your Staff

Proper training is essential to maximize the benefits of your wire label maker. Conduct training sessions that cover:

- Operational Use: Ensure employees know how to use the label maker efficiently.

- Label Design: Teach customization options that align with your branding.

2. Establish Labeling Standards

Create a guide for consistent labeling across the organization. Include information on:

- Label Content: What information should be included on each label to ensure clarity?

- Placement: Where should labels be placed for maximum visibility?

3. Regular Maintenance

Just like any tool, a wire label maker requires regular maintenance to function effectively. Schedule periodic checks and service accordingly to avoid on-the-job malfunctions.

Conclusion: Transform Your Business with a Wire Label Maker

Incorporating a wire label maker into your business operations is a move toward greater efficiency, organization, and productivity. By leveraging the advantages it offers, your company can streamline processes, enhance safety, and reduce operational costs.

At shineben.com, we understand the importance of having the right tools for work. Explore our range of packaging equipment, including top-of-the-line wire label makers, and take your business operations to new heights. Make the switch today and experience the benefits firsthand!